Advice on carbide and steel grades for different applications.

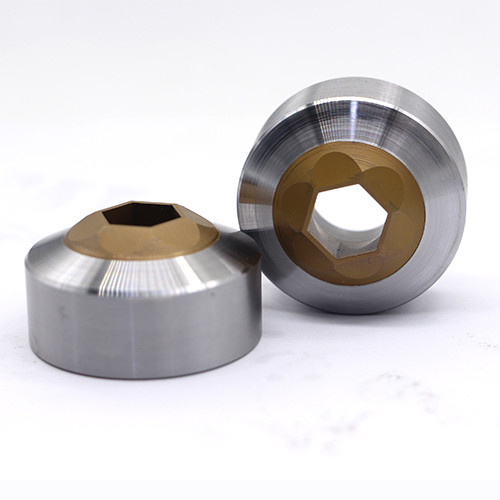

Perfect tangent radius.

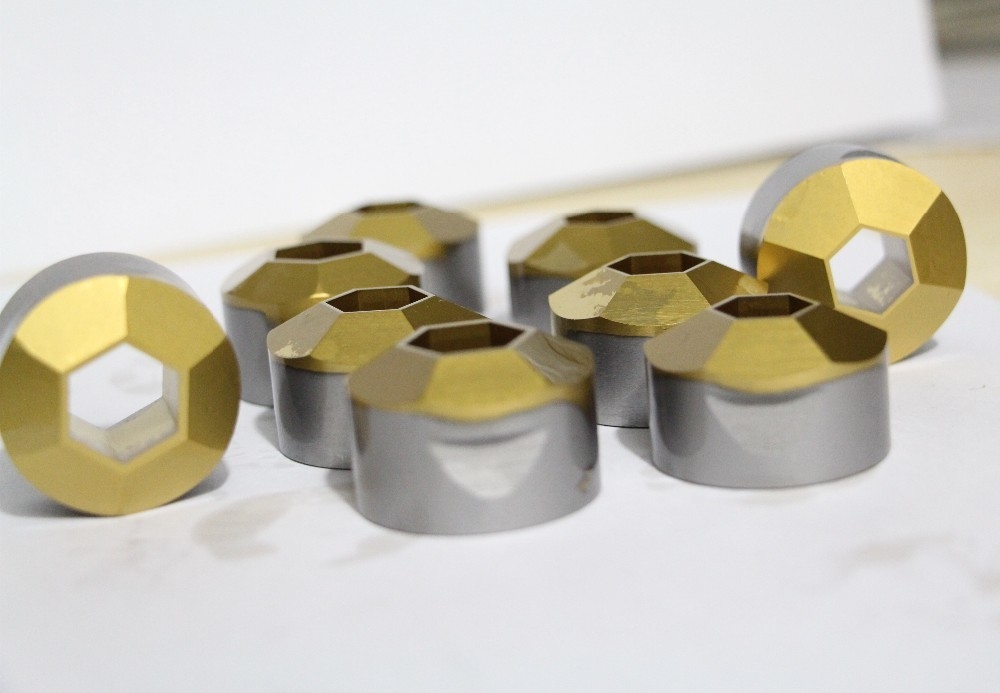

Mechanical Processing surfaces when it is geometrically possible.

Large number of shapes with very high geometric complexity.

Coating, the most suitable for the materials to be cut.

Mirror polishing before and after coating.

± 0.005 mm tolerances.

Competitive prices.

Perfect tangent radius.

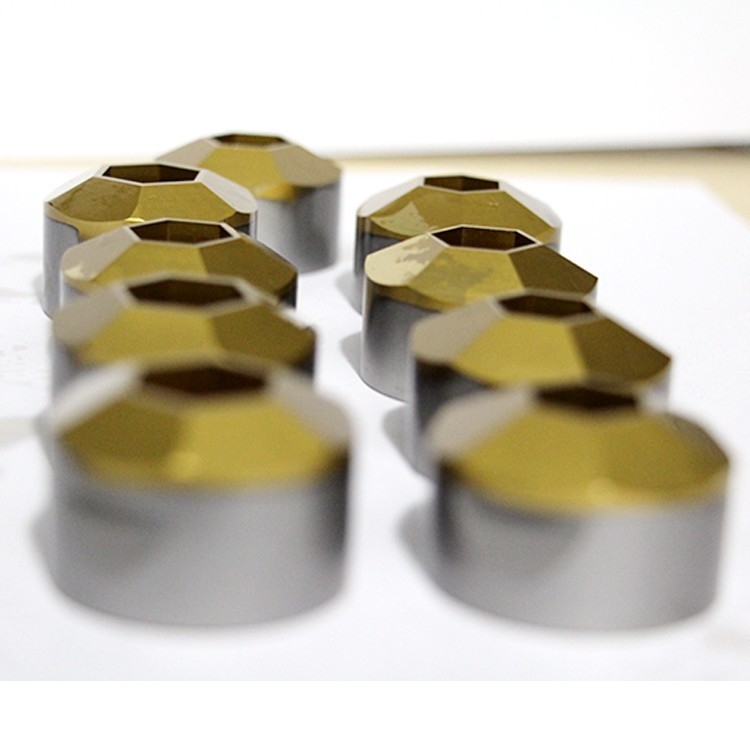

Mechanical Processing surfaces when it is geometrically possible.

Large number of shapes with very high geometric complexity.

Coating, the most suitable for the materials to be cut.

Mirror polishing before and after coating.

± 0.005 mm tolerances.

Competitive prices.