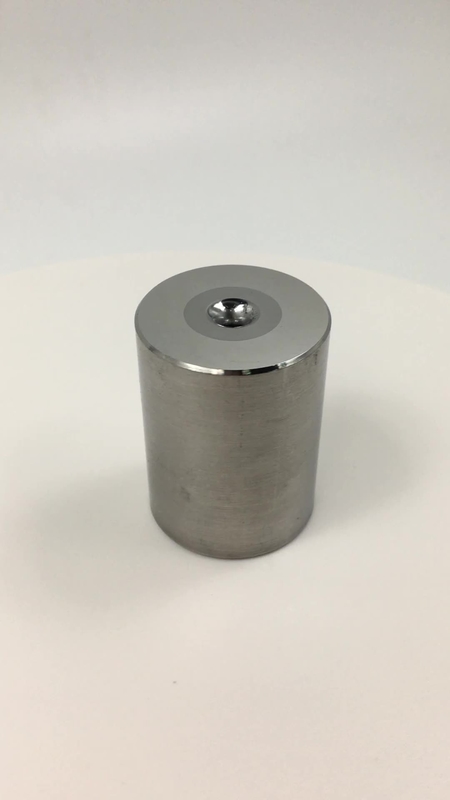

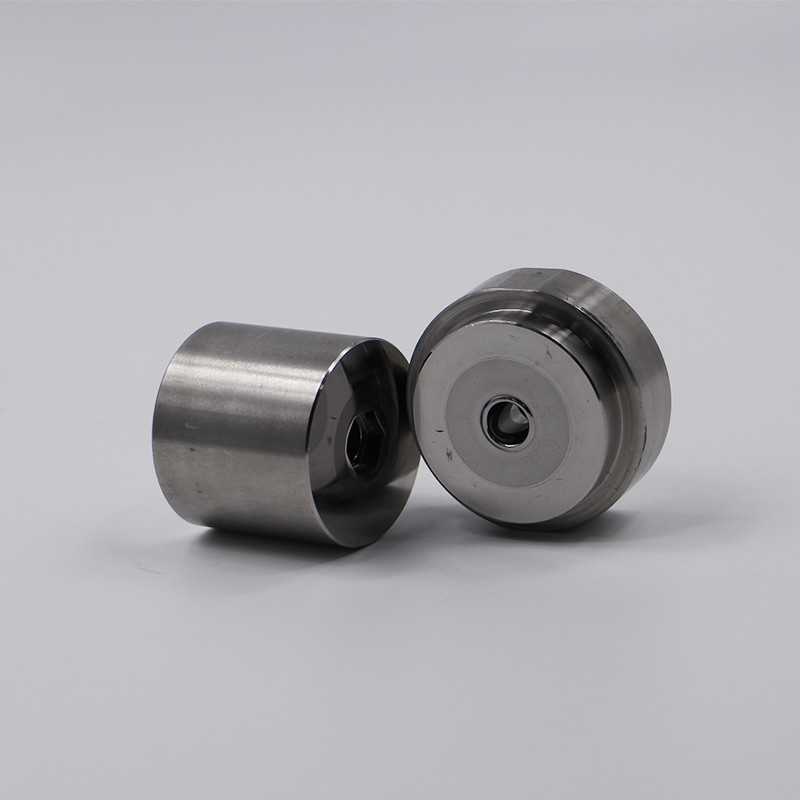

Customized Designed Hot Forging Carbide Die for Making Screws or Bolts

Product name | Customized Designed Hot Forging Carbide Die for Making Screws or Bolts | Mold type | Injection mold, below mold, die casting mold, over molding, insert molding,screw mold etc | Certification | ISO9001:2015 | Brand | Henghui | Standard | DME, HASCO, MISUMI, PUNCH, etc. | Mold material | H13, SKD61, VA80, ST7, ST6, KG5, KG6 | Cavity/core material | Slider | Lifter | Sub- insert | Mold base | S50,P20, LKM, HASCO etc. | Specification | Customized as our requirements | Mold cavity number | 1-64 Cavity | Mold runner | Cold runner and Hot runner, etc. | Mold hot runner | DEM, HASCO, YUDO, etc. | Mold cold runner | Point way, side way, follow way, direct gate way, etc. | Design software | UG, PRO-E, CAD, CAXA, Catia, Solid-work , etc. | Mold hot treatment | Including quencher, Nitridation, tempering, etc. | Mold cooling system | Water cooling or Beryllium bronze cooling, etc. | Surface treatment | Paint, Texture, polish, print, anodize, electroplating, electroforming | Hardness of the steel | 46-68 HRC | Mold life | 10,000~1000,000 shots | Lead time | 7-15 days | Mold Packing | Wooden or carton case |

|

Equipment Name | Specification(mm) | Qty(set) | Origin Making | CNC Machining Center | MCV-SV1100, | 4 | Taiwan | Lathe | C6132,CS6140 | 4 | Baoji | Hydraulic Press | HQS300T | 1 | Taiwan | Internal and external high-precision grinder | M1420 | 1 | Wuxi | Surface Grinder | MY820 | 2 | Jiangsu | Cylindric Grinder | MA1420A | 1 | Japan | Clamping Machine | HC650 | 1 | Baoji | Sawing Machine | GB4028 | 1 | Zhejiang | CNC Milling Machine | MVC1000A | 1 | Taiwan | Milling Machine | SL-30 | 1 | Taiwan | CNC Wire-Cut Machine | DK7732, DK7780 | 2 | Jiangsu | Grinding Machine | K11 | 5 | Zhejiang | EDM Machine | EDM320, EDM350 | 2 | Beijing | NC Lathe | CK6730 | 3 | Baoji | Driller | ZX7016 | 1 | Zhejiang | Cold Heading Machine | J64,J84, J104, J134, J165 | 8 | Taiwan | Automatic Lathe | --- | 4 | Taiwan | Cold Forming Machine | 11B,14B,17B,22B,24B,27B | 6 | Taiwan | Heading Machine | --- | 6 | Taiwan |

|

Advanced machines and technology talented persons guarantee the high output, high quality and high speed production

of Henghui.

Chongqing Henghui Precision Mold Co., Ltd. is a manufacturer of all kind of molds with well-equipped testing facilities and

strong technical force. Because of good quality, reasonable prices and stylish designs, our products are extensively used in

molding and other industries. Our products are widely recognized and trusted by users and can meet continuously changing of

economic and social needs. We welcome new and old customers from all walks of life to contact us for future business

relationships and mutual success!

Product service:

Mold making and screw mold ,mainly for electrical product mold, home appliance mold, automobile product mold,

commodity mold, medical product mold, any products is welcome.

We understand productivity, timeliness, quality and cost efficiency are so crucial to the bottom-line of your business and we are

here in Henghui to help. We provide ideal and unique solution to your special needs as we know every business is different.

Through communication, collaboration and coordination (3Cs),we will assist your business move closer to success.

Why Choose Us:

Our advantages | 1.High quality | 2.Reasonable price | 3.On time delivery | 4.Good After-sale service | 5.Strict quality control | 6.All the mold are automotic. | We will offer you | 1.In-time response on letters, telephone calls or fax | 2.In-time supply the quotation and mold designs | 3.In-time communication on the technical points | 4.In-time sending picture for the mold machining progress and mold finishing schedule | 5.In-time mold test and sample delivery | 6.In-time mold delivery. |

|

Henghui Provides work members with considate care and excellent working environment.

Sample Charge:

1.Sample charge:According to your design.Sample time:3-5 days

2.Sample charge: For Existing samples.Sample time:1 day

General Order information

In order to provide our clients the best service,We have set up customer management platform.

Standing in our clients’s way.,we know our clients’ demands and the problems we need to solve .

Drawings or samples provided | We get the drawings or samples from our clients. | R&D | We support customer R&D. Make the files or improve the design if you needed. design if you needed. | Quotation | According to the drawings or samples | Mold design | Send mold design for confirmation within 3 days after getting mold charge | Mold making | Start to make the mold after design confirmed | Test-run | After mold is finished, we’ll test it and get samples | Sample confirmation | Send the free samples to client to make sure perfect | (Mold modification) | (If the sample is not ok, we’ll modify the mold for free, Then send free samples to you again...until meet your demands) | (Mold delivery) | (Shipping mold out if no need to injection plastic parts, packed by wooden case by see or by air, according to client’s requirements) | Plastic Injection Service | Start to high-volume production with the ordered mold. |

|

1.Q:Are you a factory or trading company?

A:We are a factory, Henghui has 7,000 square meters of manufacturing plants and R&D bases

2.Q:Where is your factory located? How can I visit there?

A:Our factory is located in Hailong Village, Baishiyi Town, Jiulongpo District, Chongqing City, China. All our clients, from home or

abroad, are warmly welcome to visit us at anytime!

3.Q:What is the material of your products?

A:The material is DC53,SKD11,D2,SKH-9,SKH-51, or as our clients’ requirements.

4.Q: The maximum press your factory have available ?

A: Our factory has 30T,60T,160T punching machines

5.Q:How does your factory do regarding quality control?

A: Quality is priority. Henghui people always attach great importance to quality controlling from the very beginning to the very end.

Usual we choose the following ways to ship our molds, if there is any other choices or requirements, we also welcome.

For more further information please Click "Send" Now!!

It's our pleasure to provide you good quality products with good price and service always.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!