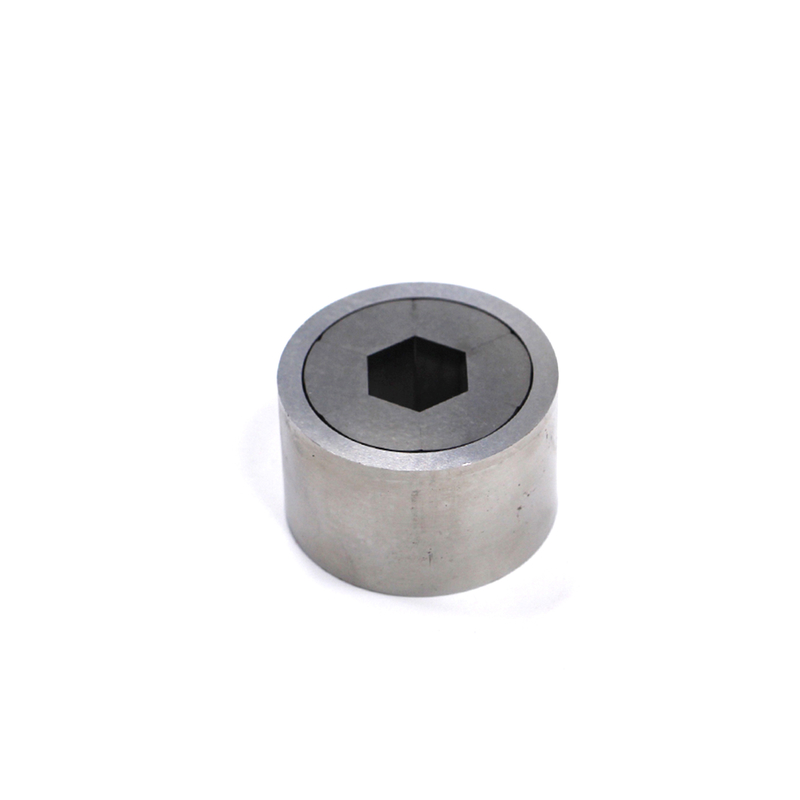

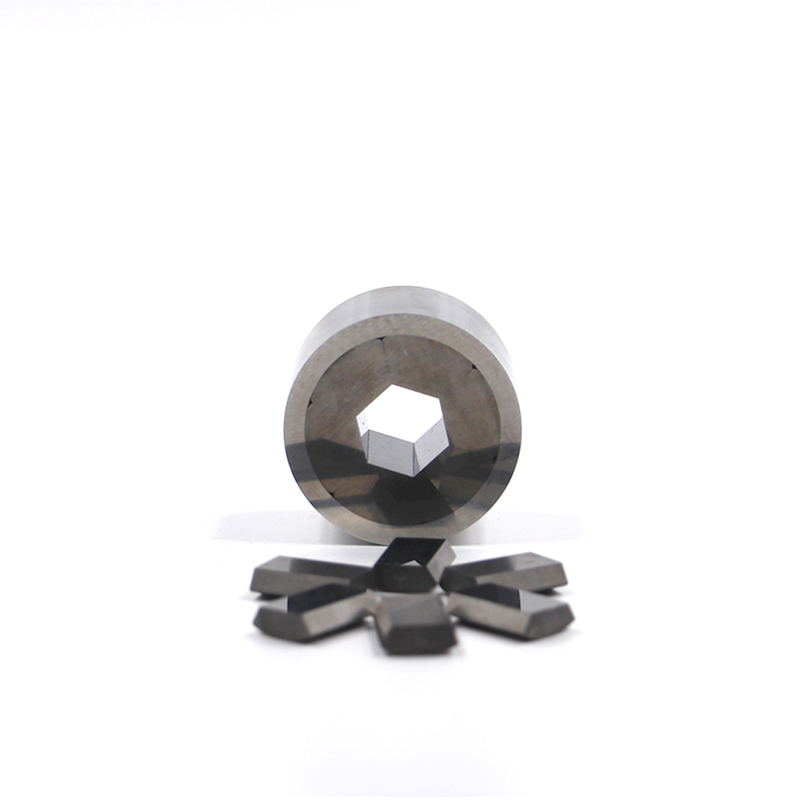

High Precision Polishing Cold Heading Die Tungsten Carbide Hexagonal Die

The main die is the main cavity in which the blank is produced. It is generally composed of mould steel (such as SKD11/SKD61) and tungsten carbide (cemented carbide).

After the wire is cut off, it is sent to the main die cavity, and the punch strikes the material left outside the main die, causing it to deform into blank.

According to the composition of the main die into ordinary mold and segmented hex die. Ordinary mold refers to the die is a whole, with the method of mechanical (such as wrench) can not be disassembled, used for forming relatively simple products. Segmented hex die refers to the combination of die, can be disassembled, used for molding screw head more complex products, each mold model is consistent with the corresponding equipment die base.

Main die selection: the length of the main die, the length and diameter of tungsten carbide of the main die should be selected according to the specification of the screw. The length of the main die tungsten carbide shall be longer than the length of the screw, the outer diameter of the tungsten carbide shall be larger than the diameter of the screw head, and the R Angle of the main die shall meet the requirements of the drawing.

The carbide cold heading dies we supply for customer including:

1. Straight hole insert mold

2.Extrusion hole insert mold

3.Cutter knife mold

4.Wire drawing mold

5.Tube drawing mold

6.Multiple-position mold

7.Miscellaneous molds for screw machine

We know clear and use different types of tungsten carbide inserted for making different type/shape of screws.

Pls provide us with the details of die case size, wire diameter,

length or screw size when you inquire or order.

It is highly suggested that you send the drawings or screw samples for our reference.

Ordering Guide:

General Order information

In order to provide our clients the best service,We have set up customer management platform.

Standing in our clients’s way.,we know our clients’ demands and the problems we need to solve .

| Drawings or samples provided |

We get the drawings or samples from our clients. |

| R&D |

We support customer R&D. Make the files or improve the

design if you needed.

|

| Quotation |

According to the drawings or samples |

| Mold design |

Send mold design for confirmation within 3 days after getting

mold charge

|

| Mold making |

Start to make the mold after design confirmed |

| Test-run |

After mold is finished, we’ll test it and get samples |

| Sample confirmation |

Send the free samples to client to make sure perfect |

| (Mold modification) |

(If the sample is not ok, we’ll modify the mold for free,

Then send free samples to you again...until meet your

demands)

|

| (Mold delivery) |

(Shipping mold out if no need to injection plastic parts,

packed by wooden case by see or by air, according to client’s

requirements)

|

| Plastic Injection Service |

Start to high-volume production with the ordered mold. |

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!