Production note

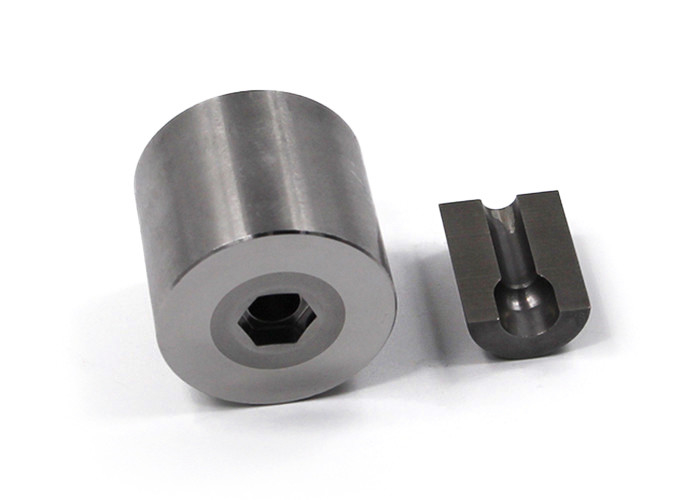

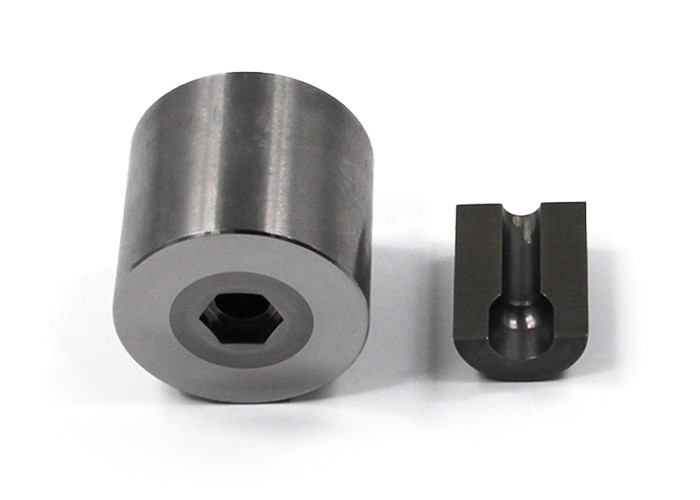

1. Select the tungsten steel materials and specifications size to make the screws or nuts mold correctly.

2.According to the difference of the forming difficulty,size,length of screws and nuts,rational design of the mold structure,multi-station and nut mold should be allocated on a reasonable basis the upsetting deformation and the number of molding.

3.The mold fine craftsmanship,accurate size,bore diameter to match the finish mirror requirements.

4.Interference voltage distribution margin,select the appropriate alloy taper size.

5.Shell steel sleeve must be rigid and good heated,and the hardness range should be between 42°c-48 °c after the vacuum heat treatment.

6.Keep the mold bore and the wire surface cleaning and smoothing, cold drawn wire must be nailed after ball annealing treatment.

7.We use diamond grinding wheel to mill the cycle and the end of tungsten

8.The technicians adjusting the master must have good technical level.

Common questions in using screws and nut mold

1.Mold and structural design experience with the master, not calculated the number of cold heading,analyzing the force of the mold deformation than the unreasonable distribution.

2.The cleanliness of the mold, the inner hole finish is not enough.

3.The rigidity of shell sleeve material, the heat resistance,and the heat treatment hardness are unreasonable.

4.In order to save the cost of production, they selected poor quality tungsten carbide steel and wire rod, alloy specifications and steal material nailing serious wheels unreasonable.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!