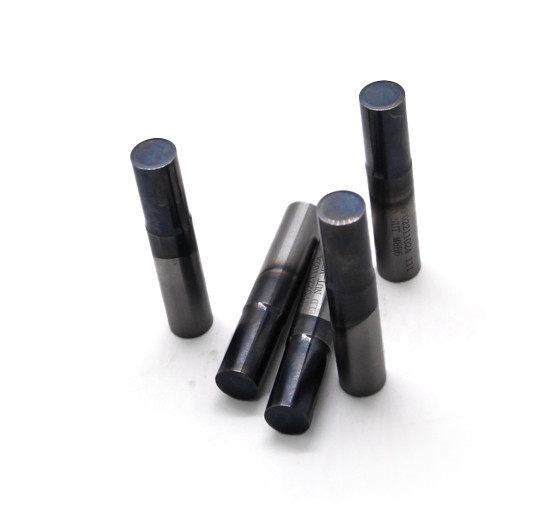

Mold Accessories Round Shaped Straight HSS Punches Pins Precision Stamping Parts

Product Features:

· All types of Punches as per DIN, IFI, ISI & JIS Standards to suit any of your production needs.

· Punches manufactured to customers specifications.

· Exceptional surface finishes for reduced friction resulting in extended tool life.

· Range of steels available to customers specifactions Consistencies of size & finish.

Product Details:

| Product name |

HSS Punch Pin |

| Matrial |

M2/M42 |

| Plating |

With Coating TiN/TiALN |

| Dimension |

Customized |

| Characteristic |

Long service life, high finish and good wear resistance |

| MOQ |

10pcs |

Product Picture:

Our Punch pins are made of high speed steel material, with DLC,TICN,TIALN,TIN ...coating supporting the long-time using. We have various pins of different standards like DIN, JIS, ISO, MISUMI, PUNCH, DAYTON, HASCO, FIBRO,LANE, etc. Moreover,we also produce different kinds of pins according to client's drawings or samples. If you have any needs, plesae do not hesitate to contact.

The material selection of the punch pin is mainly high-speed steel. The commonly used materials are SKH9, SKH55, SKH59 in Japan, M2, M35 and M42 in the United States. The main feature of the material is that the high-speed punching material can maintain good red hardness and wear resistance. There are also some powder high speed steel materials, commonly used are ASP23, ASP30, ASP60. The performance of the material is superior to that of high-speed steel, but the price is high and the range of use is relatively small. Tungsten carbide punch pins are new products that can be produced by a few companies this year. They are mainly made of tungsten carbide. They have high toughness requirements for materials, and the technical requirements and production costs during production are also high. They are commonly used in the stainless steel cold heading industry.

Material: Carbide>M42(H59)>M35(H55)>M2(H9)

| H9(M2) |

| Chemical Composition |

C |

Si |

Mn |

P |

S |

Cr |

Mo |

V |

W |

| Content (%) |

0.85 |

0.33 |

0.34 |

0.027 |

0.005 |

4.12 |

4.73 |

1.78 |

5.74 |

| |

Cu |

Ni |

|

|

|

|

|

|

|

| |

0.12 |

0.24 |

|

|

|

|

|

|

|

| M42(SKH59) |

| Chemical Composition |

C |

Si |

Mn |

P |

S |

Cr |

Mo |

V |

W |

| Content (%) |

1.06 |

0.3 |

0.31 |

0.018 |

0.002 |

3.74 |

9.29 |

1.1 |

1.34 |

| |

Cu |

Ni |

Co |

|

|

|

|

|

|

| |

0.07 |

0.29 |

7.79 |

|

|

|

|

|

|

| Product Name: |

HSS Punch Pin |

| Material: |

M2/M42/M35/Carbide |

| Profile tolerance: |

+/-0.006MM~ +/-0.008MM. |

| Surface treatment: |

Polishing,coating Treatment,Nitriding treatment,measuring,ETC.. |

| Hardness |

HRA60-68 |

| Measuring instruments: |

VMS,profile projector,pressure gauge,hardness tester,magnifying glass.etc... |

| Usage |

For making bolts or nuts |

| Design: |

Standard or un-standard parts,according to customer's requirement. |

| Processing machinery: |

Wire EDM, CNC milling and turning, laser cutting, drilling, grinding, bending, stamping, welding, etc. |

| Drawing software: |

AUTOCAD,pro-engineer,UG,moldflow,etc.. |

| Application: |

machinery equipment,Heavy industries parts&tools,medicine,chemical,etc... |

| Quality control: |

100% inspection before shipping. |

| Customization: |

OEM ODM service |

About Us:

Chongqing Henghui Precision Mold Co., Ltd located in Chongqing, which is specialized in developing, production and sales of various tungsten carbide dies manufacturer. All our products are made from high-precision manufacturing equipment and testing equipment. Using advanced processing technology to ensure products’ precision. At the same time, we also have technical engineers with many years of professional design experience, a group of experienced technical and quality inspection personnel, implemented the ISO 9001 quality management system and ERP system management.

Our products and services cover the Asian market in China and are exported to Europe, America and Southeast Asia. Our carbide die have a reputation for precision, efficiency, stability and durability. We have a customer service experienced sales staff to provide customers with more attentive service and create more value.

Advantages:

1.High quality

2.Reasonable price

3.On time delivery

4.In-time sending pictures for the mold machining progress and mold finishing

schedule

5.In-time mold test and sample delivery

Packing and Delivering:

F&Q:

Q1::Are you a factory or trading company?

A1:We are a factory, Henghui has 7,000 square meters of manufacturing plants

and R&D bases

Q2:Where is your factory located? How can I visit there?

A2:Our factory is located in Hailong Village, Baishiyi Town, Jiulongpo District,

Chongqing City, China.

All our clients, from home or abroad, are warmly welcome to visit us at anytime!

Q3:What is the material of your products?

A3:The materials are DC53,SKD11,D2,SKH-9,SKH-51, or as our clients’ requirements.

Q4: The maximum press your factory have available ?

A4: Our factory has 30T,60T,160T punching machines

Q5::How does your factory do regarding quality control?

A5: Quality is priority. Henghui people always attach great

importance to quality controlling from the very beginning to

the very end. All the molds, the QC measure with three-D

measuring equipments regularly.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!