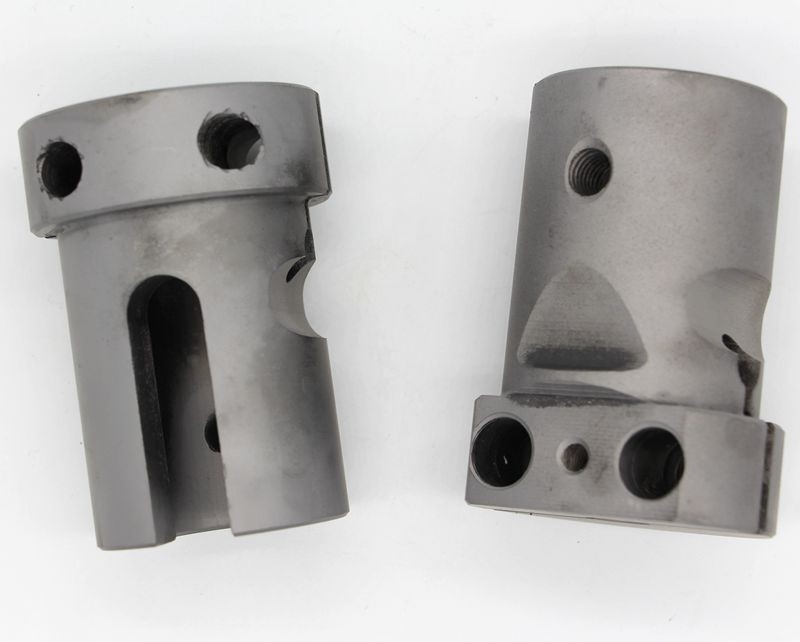

Nut Dies are exclusively used in fasteners industry to make fasteners of high strength and high specification required for specific purposes by the various industries. Hexagonal, Square & Round are the most common shapes of nuts are designed from these Dies of high strength that can bear large impact of pressure and stress. Both standard and non standard nuts are manufactured by using these high quality Dies. Material used in making these Dies is very much specific having unique composition to provide certain essential characteristics of strength, perfection, anticorrosion property with super fine and smooth finish of international standards.

Since our foundation, Henghui have become the foremost company of a broad assortment of Nut Forming Dies. The offered dies are manufactured by utilizing advance techniques and utmost quality raw material as per the industrial standards. Apart from this, our offered dies are inspected on numerous quality parameters in order to ensure its durability and quality. Clients can avail these dies from us in varied sizes & shapes at industry competent prices.

Henghui will choose the suitable carbide materials of products, combined with perfect technology, makes the carbide dies to achieve a better life.Tungsten carbide straight hole dies with the property of high wear resistance, good polishing performance, low friction coefficient, etc.and has very high compressive strength.

Even today, steel mold are still in use due to they're cheap, as tungsten carbide parts tend to cost more up front. The performance benefits that tungsten carbide dies have to offer, however, easily justify their price point.

The primary advantage of tungsten carbide die is strength. Carbide dies, which are notable for offering more satisfactory performance than steel counterparts, tend to last significantly longer, too – even in extreme conditions. Thanks to this durability, our tungsten carbide dies require replacement much less often than typical steel dies, which not only reduces overall maintenance costs, but lessens machine downtime as well.

Features

• 100% quality guarantee

• Various size for selection

• Professional technical support

• OEM & ODM are welcomed

• Small order is acceptable

• Factory service with competitive service in the market

• Delivery in time

• Flexible payment terms(T/T, western union, etc.)

• Best after-sales service

Packaging & Shipping

Usually, we choose the following ways to transport our molds, if you have other options or requirements, we are also welcomed.

Why Choose Us

Our advantages:

1.High quality

2.Reasonable price

3.On time delivery

4.Good After-sale service

5.Strict quality control

We can offer you:

1.In-time response on letters, telephone calls or fax

2.In-time supply the quotation and TRIMMING DIE designs

3.In-time communication on the technical points

4.In-time sending pictures for the die machining progress and die finishing schedule

5.In-time mold test and sample delivery

6.In-time delivery.

FAQ

Q1:Are you a factory or trading company?

A1:We are a factory, Henghui has 7,000 square meters of manufacturing plants and R&D bases

Q2:Where is your factory located? How can I visit there?

A2:Our factory is located in Hailong Village, Baishiyi Town, Jiulongpo District, Chongqing City, China.

All our clients, from home or abroad, are warmly welcome to visit us at anytime!

Q3:What is the material of your products?

A3:The material are die steel, tungsten carbide, HSS(high speed steel), or as our clients’ requirements.

Q4: The maximum press your factory have available ?

A4: Our factory has 30T,60T,160T punching machines

Q5::How does your factory do regarding quality control?

A5: Quality is priority. Henghui always attach great importance to quality controlling from the very beginning to the very end. All the molds, the quality control measure with three-D measuring equipments regularly.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!